How Dual Fuel Systems Help You Save Year-Round

Benefits of Combining Electric and Gas Heat If you live in North Carolina, you know the weather can be a rollercoaster—swelteringly unbearable summers, chilly winters,

Carbon monoxide (CO) is toxic to humans because it is attracted to hemoglobin, the main component of red blood cells. Normally, hemoglobin carries oxygen throughout our bodies, releasing it to tissues as needed. When CO gas is present, it replaces the oxygen, and in heavy concentrations, can kill in minutes. In low concentrations the symptoms mimic the flu or other viruses common during cold weather months.

Here are five simple steps to help you prevent the “invisible killer” from entering your home:

A dual fuel heat pump is an air-source heat pump designed to be installed and work with a forced air furnace heating system. The forced air furnace can be new or existing.

In more simple terms, it’s a heat pump when the outside temperature has enough heat content to be extracted for heating your home. When that temperature falls below 40 to 35 degrees the compressor begins to be reduced in the amount of heat it can produce. By the time the temperature falls to 20 degrees outside, the compressor is 100% inefficient. That means it will use still draw the same amount of power but produce NO heat content (COP=0).

With conventional heat pumps the auxiliary heat (electric heat strips) comes on to help keep you warm when the compressor alone can’t. While the electric strips give you 100% of the power that’s put into them (COP=1), those electric strips are crazy expensive to operate; it’s an expensive and inefficient way to stay warm.

A dual fuel (hybrid) system fixes this problem by turning off the compressor when the outside temperature falls below the pre-set threshold (usually 40 or 35 degrees) and the compressor is starting to use more and more energy for less and less heat being delivered into the house; if it’s not producing then why run it? However, instead of going to the most expensive means to heat your home (electric heat strips) a gas furnace is employed for this task. Natural gas is second only to the heat pump (above 40 degrees outside) in producing heat for your home. So, when the temps are above the pre-set threshold you have the least expensive (conventional) way to heat your home and when they drop too low you get to go to the second least expensive way.

In effect you’re buying a heat pump system and a gas furnace system at the same time and that does cost more upfront. It’s nowhere near double but it’s more expensive upfront to buy but the long term savings can and usually do offset that cost. Over a period of 5-8 years (depends on how you operate it) the system will have paid for itself in savings realized and now you will actually start to see a return on your investment – often a sizable ROI. Dual fuel heat pumps aren’t for everyone but they are a great way for some folks to see even greater saving and get even more efficiency from the heating system.

We borrowed heavily for this from an HVAC company in Santa Clarita, CA called ASM. No need for us to reinvent the wheel when so much of this information is boiler plate material and it changes little, if ever, over time. However, it’s really important information that most consumers just don’t know about or at best are confused about. Understanding these better will help you make a better choice and probably save you money in the process. We hope you find this helpful.

Buying an Energy Star® rated appliance(s) is an important first step. To go a step further in reducing your energy costs, look at the type of energy that you are using, and try to find the most efficient of the Energy Star® rated products that apply. Some products don’t meet all the requirements for Energy Star® but are still wonderful nonetheless. No one thing should be taken as the “litmus test” for efficiency but together they can paint a very clear picture of the overall efficiency and help save you money over time.

Most of us have heard the term SEER by now. This might be the first time you’ve seen it written though. It’s one of those dastardly acronyms that the Federal government loves to use. It’s become a big part of the HVAC lexicon but unfortunately too many use it wrong at worst or are confused about what it’s true worth is at best. We’ll try to unscrambled the acronyms for you and hopefully it will help you make a better HVAC buying decision the next time you are faced with doing that.

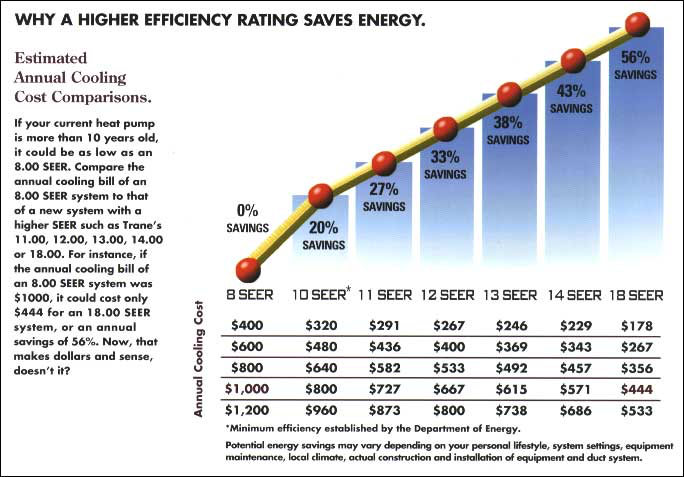

Buying equipment with a high Seasonal Energy Efficiency Ratio (SEER) and a high Energy Efficiency Ratio (EER) is a valuable way to save big money on you cooling bills. These are both important and yet very different ways to measure the efficiency of a cooling system and often they are actually at odds with one another. Before tackling SEER vs EER lets take a look at each individually, starting with SEER.

SEER is the most common way to evaluate an air conditioner’s efficiency. Now it is important to understand that this is only a measure of cooling power, and applies only to air conditioning. An air conditioner’s SEER rating is the ratio of the cooling output of an HVAC unit over a typical cooling season (measured in British Thermal Units, or Btu’s), divided by the energy consumed in Watt-Hours. It is the average over a cooling season, and is calculated using a constant indoor temperature and varying outdoor temperatures ranging from the 60’s to over 10-degrees. SEER also uses average US household energy expenditures in its calculation. A unit’s SEER value is displayed on its Energy Guide Tag (left) as a number ranging from around 8 to 30, although right now there are few air conditioning units more efficient than about 23-SEER. So for instance, an air conditioner with a value of 23-SEER will be far more efficient than a unit with a rating of 14-SEER.

EER is a more technical and objective method…but it has its limitations, too. Again, EER stands for Energy Efficiency Ratio, and is actually an older means of calculating energy efficiency than SEER, having been used since 1975. Like SEER, an air conditioner’s EER rating is a means of measuring an air conditioner’s efficiency, but where SEER is a means of measuring seasonal efficiency, an HVAC system’s EER is more of a constant. Simply put, EER is more of an engineering number, than a marketing number, and will probably be used by an HVAC mechanic when talking to others in the profession. EER values are also often encountered when looking at smaller window AC units for which calculating a SEER value would be impractical. EER is calculated using a constant outside temperature of 95 degrees, a constant inside temperature of 80 degrees and a humidity level of 50%. No seasonal temperature changes are factored into a unit’s EER rating. Simply put, the EER is obtained by creating that environment above in a lab, plugging the unit into the electrical outlet and then watching the meter go around. The less it goes around in those exact conditions the better. We can then compare different equipment against one another and get a measure of their efficiencies.

The Advantages of an Air Conditioner’s EER Rating.

If you read the section on a unit’s SEER value, then you know that SEER is a good approximation of a unit’s efficiency if the average summer temperature in your area is around 83 degrees, but can be misleading if you live in say…Central North carolina. Conversely, an EER value is an objective, set standard that can be used to directly compare two air conditioning units without worrying about the seasonal changes in your area. For instance, how a 16-SEER rated air conditioner operates during the summer in Bozeman, Montana is far different from how it will perform in a Santa Clarita, California, or Raleigh, North Carolina or Bar Harbor, Maine summer.

Now that you know about energy ratings, you can start shopping for more energy efficient air conditioners. For more information on the energy efficient Carrier Infinity-21 Series or the Amana-18, check out:

When to Use SEER vs EER.

So now that we know the differences between SEER vs EER, we can take a look at when to use each. Like we discussed, SEER is a great way to get an idea of how a unit operates throughout a cooling season, and a unit’s EER is an objective way to measure an air conditioner’s efficiency.

SEER is most commonly used method. SEER can be used to compare one AC unit to another directly and is most commonly encountered when looking at large, central air conditioning units. A 16-SEER is more efficient than a 14-SEER regardless of who the manufacturer is air what model name it’s given. With SEER bigger is better (about the only place that’s true in HVAC). However, it should not be used to measure how much money your new air conditioner will save you. Remember, a SEER rating is based on a standard test across a specific seasonal temperature range and as we discussed that range varies from town to town and really varies from state to state and region to region. As such, a percentage increase or decrease from the current SEER level to the proposed SEER level will give you an approximation of your potential savings.

EER ratings are more commonly encountered with smaller window mounted air conditioners. An air conditioner’s EER rating is best used to objectively compare air conditioners or to do any type of load or engineering calculations. Because it is not diluted by additional inputs, the EER value, in my opinion, is the most accurate way to compare two different HVAC units for the purposes of using Manual-J Load Calculations.

At the end of the day, SEER and EER can be very useful for comparing different air conditioning units to one another, but are not the end of the road to increasing efficiency and decreasing energy costs.

As I stated before most people have at least heard of the SEER acronym but almost no one outside of the HVAC industry has ever heard the acronym HSPF. This stands for Heating Service Performance Factor. Technically speaking, the HSPF is a heat pump’s estimated seasonal heating output in Btu’s divided by the amount of energy that it consumes in Watt-hours.

The important takeaway from this is that the HSPF is a seasonal measure – much like SEER is also a seasonal measure. In short, HSPF is the same as SEER but for heating instead of cooling. As with SEER, a heat pump with a high HSPF is more efficient than a heat pump with a low HSPF. As with SEER you can’t just use the HSPF to determine the amount of savings you might experience. It’s another tool for you to use in making a better purchasing decision…not a monthly budgeting decision.

New heat pumps manufactured after Jan 1, 2015 are required to have an HSPF of at least 8.2. The very most efficient heat pumps have an HSPF of 13.

The Coefficient Of Performance (COP) is a measure of the amount of power input to a system compared to the amount of power output by that system.

The COP is therefore another measurement of efficiency; the higher the number, the more efficient the system is. The COP is dimensionless; environmental conditions are NOT factored in. The COP is also an instantaneous measurement in that the units are power which can be measured at one point in time. HVAC mechanics and engineers commonly use COP for analytical endeavors more than consumer information and buying decisions.

One common way to use COP is to consider a simple electric heater strip (a heat pump’s auxiliary heat). All of the electricity that is input to the unit is converted to heat. There is no waste and the power output (in heat) equals the power input (in electricity), so the COP is one. This can be useful in testing a systems capacity and the performance of the heaters themselves. However, this number alone doesn’t tell the complete story. Although electric heaters have a COP of 1 they are also the most expensive way to heat your home here in NC (outside of just burning money in the fireplace, I guess).

If you want to use COP to determine cost effectiveness it gets a bit involved. I’ll save you the math here, a heat pump without the auxiliary heat strips on is the most cost effective of the common methods and electric heat strips is by far the worst. A natural gas furnace and an LP gas furnace fit in the middle, respectively. Dual fuel (Hybrid) systems are great around Central North Carolina because they use the most cost effective method (heat pump compressor) and when needed they use the second best method in the form of a gas furnace. Standard heat pumps, when it’s needed go from the best method straight to the worst. Of course dual-fuel (hybrid) systems cost more upfront, too. So, all of that has to go into the ROI equation.

Annual Fuel Utilization Efficiency can be thought of as being something like SEER or EER ratings for your air conditioner. However, AFUE is used to measure the efficiency of your furnace. AFUE is actually far simpler to read and understand SEER or EER have ever been. A furnace’s AFUE rating is listed as a percentage of how much fuel it can convert into usable heat, with a scale ranging from around 30-100. For instance, a furnace with an AFUE rating of 85 would mean that 85% of its fuel is translated into usable energy that can then be used to heat your home. The remaining 15% is lost through the flue. Simply put, Annual Fuel Utilization Efficiency is the percentage of fuel used that a furnace actually delivers into your home as heat. The higher the number, the better your furnace is at doing this.

AFUE is important, but if it is price that you are concerned with, your type of fuel has a bigger effect on your annual expenses. Different fuels can be combusted at different efficiency rates. For instance, electricity is the only means of heating with a 100 AFUE rating but this efficiency comes at a high price. Efficiency is not the same as cost. Unlike air conditioning, your furnace’s AFUE is not the largest factor that affects your annual heating expenses – your type of fuel is.

AFUE can be used as a means of comparing two different furnaces of the same kind (i.e., brand X’s propane furnace vs brand Y’s propane furnace), it cannot be used to directly compare the cost to operate two different types of furnaces (i.e. propane vs natural gas.

Thermal Expansion Valve

Flow control, or metering, of the refrigerant is accomplished by the use of a temperature sensing bulb, filled with a similar gas as in the system that causes the valve to open against the spring pressure in the valve body as the temperature on the bulb increases. As the suction line temperature decreases, so does the pressure in the bulb and therefore on the spring causing the valve to close. An air conditioning system with a TX valve is often more efficient than other designs that do not use one.

A thermal expansion valve is a key element to a heat pump; the cycle that makes air conditioning, or air cooling, possible. A basic refrigeration cycle consists of four major elements, a compressor, a condenser, a metering device and an evaporator. As a refrigerant passes through a circuit containing these four elements, air conditioning occurs. The cycle starts when refrigerant enters the compressor in a low-pressure, moderate-temperature, gaseous form. The refrigerant is compressed by the compressor to a high-pressure and -temperature gaseous state. The high-pressure and -temperature gas then enters the condenser. The condenser converts the high-pressure and -temperature gas to a high-pressure liquid by transferring heat to a lower temperature medium, usually ambient air.

The high pressure liquid then enters the expansion valve where the TX valve allows a portion of the refrigerant to enter the evaporator. In order for the higher temperature fluid to cool, the flow must be limited into the evaporator to keep the pressure low and allow expansion back into the gas phase. The TXV has sensing bulbs connected to the suction line of the refrigerant piping. The sensing bulbs give temperature readings to the TXV to adjust flow of refrigerant.

Function

Expansion valves are flow-restricting devices that cause a pressure drop of the working fluid. The valve needle remains open during steady state operation. The size of the opening or the position of the needle is related to the pressure and temperature of the evaporator. There are three main parts of the expansion valve that regulates the position of the needle. A sensor bulb, at the end of the evaporator, monitors the temperature change of the evaporator. This change in temperature creates a change in pressure on the diaphragm.

For example, if the temperature in the evaporator increases, the pressure in the diaphragm increases causing the needle to lower. Lowering the needle allows more of the working fluid into the evaporator to absorb heat. The pressure at the inlet of the evaporator affects the position of the needle and prevents the working fluid from flowing back into the compressor. Since the pressure before the valve is higher than the pressure after the valve, the working fluid naturally flows into the evaporator. The pressure at the inlet of the evaporator acts on the diaphragm. There is also a spring providing a constant pressure closing the valve needle. The spring constantly restricts the amount of working fluid entering the evaporator.

THE PRESSURE SPRING CAN BE ADJUSTED TO INCREASE OR DECREASE PRESSURE BASED ON TEMPERATURE NEEDS. THE PRESSURE CREATED BY THE SPRING ACTS ON THE OPENING OF THE VALVE. WHEN THE PRESSURE OF THE SENSOR BULB ACTING ON THE DIAPHRAGM IS GREATER THAN THE COMBINED PRESSURE OF THE EVAPORATOR AND SPRING, THE VALVE OPENS TO INCREASE THE FLOW RATE OF THE WORKING FLUID. AN INCREASE OF FLOW RATE LOWERS THE TEMPERATURE OF THE EVAPORATOR AND ALLOWS FOR MORE HEAT ABSORPTION.

Benefits of Combining Electric and Gas Heat If you live in North Carolina, you know the weather can be a rollercoaster—swelteringly unbearable summers, chilly winters,

Save Up to $2,000 on Costs of Upgrading to Heat Pump Technology These energy-efficient home improvement credits are available for 30% of costs – up

Ready to slash your energy bills and boost home comfort? This rebate season presents a prime opportunity! Leaky ductwork could be silently costing you a

Understanding Leaky Ductwork Leaky ductwork is a common issue. It is where heated or cooled air escapes from HVAC systems into areas like crawlspaces, attics,

One often-overlooked issue that can lead to costly repairs is a low refrigerant level in the HVAC system of a home. Refrigerant, commonly referred to

A Guide for Realtors and Home Buyers When it comes to buying or selling a home, the focus often lands on curb appeal, storage space,

We pride ourselves on serving the Raleigh, NC area for 45 years. Trust us to get you comfortable quickly.

© Greer's Heating & Air 2025